Sinkage of the paint surface is a usual repairing defect in shop processes. This defect occurs when the final coat dried in the refinished area.

How to avoid sinkage?

Cause 1: Inappropriate preparation of intermediate coat.

In some cases, you paint the finish coat without leaving enough time to dry the intermediate coat. Because the intermediate coat is not completely dry, it is prone to result in sinkage or other painting defects under the influence of the environment.

Cause2: The thickness of coating.

If the body filler is applied too thick, it is more likely to fall off because the interior is not dry or there are cracks. That means thick coat will not only cause the paint surface to sink, and also the body filler to lose adhesion power.

Cause3: Paint sinkage is also ascribed to incomplete sealing of repaired area or too thin.

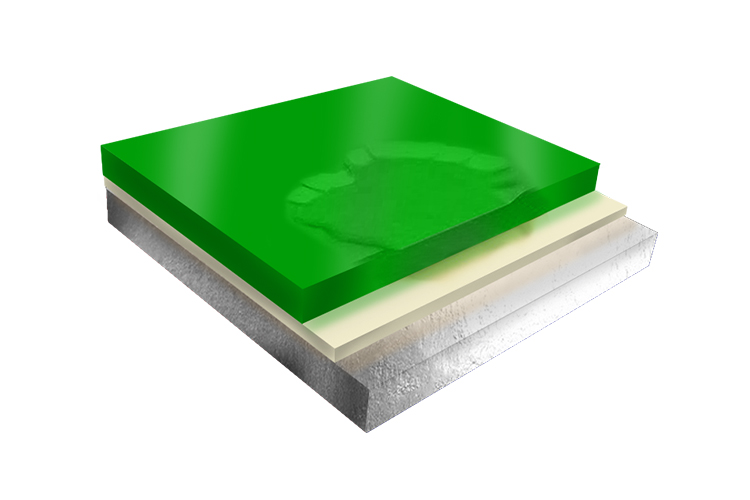

Epoxy primer or sealer is a necessary material to protect the bare metal substrate from being corroded by some chemical compositions in the upper coats. If sealing coat doesn’t work well, the repaired area will sink gradually since the bare metal reacts with paints.

Cause4: Incorrect putty operation.

Putty has water absorptivity If it doesn’t fully fill the holes in the body, the water in the air remains in the putty coat, which will form sinking. When spraying low gloss medium primer, it is not easy to be found. While spraying high gloss topcoat, paint sinkage will be spotted.

Cause5: The failure to prepare patch edges.

Smooth patch edge is one of the keys to ensure that the repaired area looks consistent to the original body. If patch edges are not prepared correctly, the chances of paint sinkage will increase.

There are some tips about avoiding the sinkage happens.

1. Provide sufficient drying time between coats. The safest way to ensure that the film is completely dry is to bake the film. Remember to set proper baking time and temperature under the instruction of paint suppliers.

2.Seal the surface completely. If the metal of the body has been exposed, spray 1-2 layers of epoxy primer to seal the surface. Remember to sand and clean the surface before painting.

3.Follow the instruction of putty. Make sure the correct preparation of putty. First, mix the putty with hardener in a proper ratio. Too much hardener will make the coat crack, and too little hardener will affect the drying time. Second, scrape a thin layer of putty for the first time and press it firmly, and then scrape the second time after the surface is dry. After each application, the area of putty application should be gradually expanded. The putty in the patch edges should be thin and form a slope.

What if the paint has sunk?

We should first assess the defect of the paint surface. If the sinkage only occurs in the topcoat, thing is not too serious. We can sand the flaw and repaint the topcoat. If the paint sinkage area is too large and too deep, you will have to carry out the repainting process from start.

Customer Service 1

Customer Service 1